| Tel Aviv Light Rail | ||

|

Dankal (commonly known as the Tel Aviv Light Rail) is a planned mass transit system for the Tel Aviv metropolitan area in central Israel. The system will include different modes of mass transit, including rapid transit (metro), light rail transit (LRT), and bus rapid transit (BRT). Overseen by the government agency NTA, the project will complement the intercity and suburban rail network operated by Israel Railways. |

||

| Road 531 | ||

|

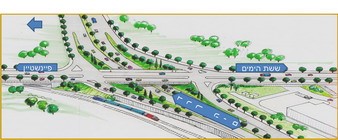

The section under construction today shortens the arrival time from the Sharon area to Tel-Aviv, saves the Israeli economy hundred of thousands of Shekels as well as opening multiple accessibility alternatives to the road users.

The road a double sided, three way path for 14 Km. A railroad track is being built as part of the project. OG Engineering is managing this project, the 4 Billion Shekels budget, the timeline and construction quality. |

||

|

|

||

|

||

| Depot project in Be'er Sheva | ||

| Construction of a bridge and associated tracks in the Depot project in Be'er Sheva, including control and monitoring structures supporting the depot. | ||

|

||

|

Ashkelon Depot project |

||

|

The project includes, among other things, the paving of 11 km of tracks, the construction of a 350-meter preparation platform for the treatment of electrified railway systems, and the construction of engineering structures, an electrical structure, a water reservoir and pumps.

The purpose of expanding the complex is to provide a solution for the housing and care of electric trains, maintenance and operation of mobile equipment of the Israel Railways, increasing the number of tracks that exist today in the complex. |

||

|

||

| 4th Railway in Ayalon Canal | ||

|

Performing piles drilling in 4th railway in ayalon road of various diameters and lengths, first step in expanding the Ayalon Highway. Ensuring the drainage of the Ayalon River canal and arranging access routes to and from outside the canal. |

||

|

|

||

|

||

|

Haifa Port |

||

|

Construction of Bay Port Terminal and Maintain for 25 years (B.O.T). Construction of Yard – Sand Backfilling, Construction of Road and parking yards, including Storm water & Daring system, portable water/Sea water/Fire water pipe line. Electrical and Lighting system including Generator & substations, communication works. Construction of RMG Beam for Crane reals including Container beam and other structures. Construction of App. 29 Buildings in a total of 11,000 sq. meters Duration of project: 3 years. |

||

|

||

|

||

|

||

|

||

|

Israel Ports Company tendered works to build the port south by NIS 3.3 billion.

The works include construction of a working quay, extension of the existing main breakwater by 600 meters, constructing 1,500 meters of secondary breakwaters, constructing quays, with a main quay 800 meters in length and a 17.3 meter depth of water, constructing storage and operating areas, and dredging.

|

||

| Israel Railway Electrification – Israel Railways | ||

|

In view of the development trends of Israel Railways, the increasing demand for rail transport and the demand for increased service, it was decided to implement the electric program to replace the existing diesel (electric) propulsion system. Electric propulsion is a more modern, reliable and economical method than diesel propulsion. In the framework of the installation of the electric program and in accordance with Subsection 18, the OCS infrastructure will be established in the first stage over the railway lines on main lines of 420 km. Cargo trains are not included in the electric program and are expected to continue operating on a diesel-powered basis. The project will begin in 2016, and the railway network will be gradually activated by 2021. The first line will be the highway between Tel Aviv and Jerusalem. |

||

|

||

|

Rails Geometry Testing for Wear & Corrugation |

||

|

3D cameras using the triangular principle are applied for non-contact continuous scanning of the rail profile. |

||

|

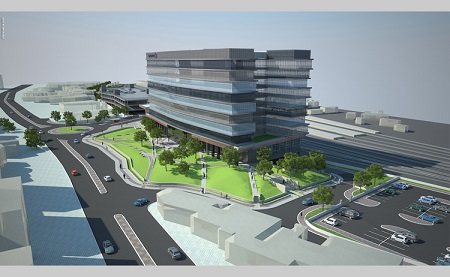

Train Station - Lod, Israel

|

||

|

The planned project is the construction of an office building for Israel Railways. The project is for an area of about 30,000 square meters, a building of typical office floor plans of about 2,200 square meters and development work around the office building and parking lots. OG Engineering will manage the quality control system for the contractor.

|

||

|

|

||

|

|

||

|

|

||

|

||

|

Train Station - Sederot, Israel

|

||

| The Sderot Train Station Project includes passageways (underground and overhead), platforms, Command & Control building, buildings for passenger arrivals, roads, and development & landscaping works.

The total built area will be about 3,000 square meters and, in addition, there will be two platforms, each about 300 m in length. The project is being established as part of the Ashkelon - Netivot railway line. The station is located at the junction of Highway 34 and Menachem Begin Boulevard - the main entrance road into Sderot. The buildings in the Station are:

Building C - underground passageway Building D - Main building, access to the platforms Platform Building Command & Control Building Roads, parking lots and development building.

|

||

|

||

| Train Station – Beer Sheva, Israel | ||

Beer-Sheva Train Station: The project constitutes the construction of a train service station for arriving trains. A refueling depot, a train-washing structure, a control tower and garage buildings have been erected at the station where the trains receive maintenance and preventative services. The aforesaid is similar to an airport for aircraft, just from the aspect of trains. |

||

|

|

||

|

|

||

|

Israel Highways - North of Israel

|

||

The project deals with the process of routine maintenance work of roads in the northern district, in the field of installing safety railings and renovating paint jobs. As part of the ongoing maintenance of safety railings and repainting due to the natural wear and tear process, or as a result of necessity due to traffic accidents, road works, etc., a damage - repair process is implemented for the purpose of ensuring the efficient functioning of the road. |

||

|

||

Casting Foundations for a bridge - Highway 65

|

||

|

||

|

Highway Improvments - Gimzu Junction

|

||

|

This project will include broadening, repaving and arrangements of traffic and drainage at a junction of 443 and 444 and Junction Gimzu. The project will undertake, among other goals, the expansion of road segments on both sides, drainage works, lighting installation, installation of new traffic signals, scrubbing and covering each section and installation of steel railings on the sides and in the middle of the road. |

||

|

|

||

|

||

|

Rehovot – Highway/Railroad Crossing Separation

|

||

|

Project consists of erection of bridge for North/South traffic over heavily travelled west entrance to city and adjacent parallel train tracks to eliminate signaled level intersection. The 1st phase consists of rerouting of conflicting underground utilities including sewer, water, storm drains, electric and communication lines in order to prepare bridge foundations. The significant challenge is working adjacent to vehicular traffic. |

||

|

|

||

|

|

||

|

Improvement of Access Road, Eshkolot Israel |

||

|

The proposed project is an expansion, construction and adding road railings to the access road to Eshkolot settlement. The project includes widening the road on both sides, scrubbing and tarring the road, installing steel rails on the sides, building separation walls and adding light poles at the junction. OG Engineering conducts Quality Control services for project.

|

||

|

||

| Depot and Depot Portal - Petach Tikva | ||

|

Site location: North Industrial Area of Kiryat Aryeh, Petach Tikva. The Depot and Depot Terminal project goal is to build the operational maintenance center for the red train line and connect between it and the tunnels. Project contains: Building the maintenance and operations buildings, infrastructure, concrete walls, development works, electrical and communication systems, rails and roads. |

||

|

||

|

Train Station Ha’Uma - Jerusalem |

||

Building a fast train line to Jerusalem is a national mega-project, it will connect the capital of Israel with Gush Dan metropolitan area. Aimed at creating a fast rail link between Jerusalem and the central region, and will alleviate traffic congestion between Jerusalem and central region.

The project includes the construction of a double track length of about 38 km from the railway of Ben Gurion Airport and Jerusalem-Modi'in, and the establishment of a station between the ICC and the central bus station in Jerusalem, at a depth of 80 meters under the street level.

- Planned length of line: 38 km

- Planned tunnel length: 5 tunnels with a total length of 37 km (some double tunnel) - Planned length of bridges: 10 bridges with a total length of over 6 km - Train lines will operate using electric power system - Expected travel time: 30 minutes (between Tel Aviv and Jerusalem) |

||

| Ben Gurion Airport - Israel | ||

|

Project Purpose: Perform various work on Extension E and the eastern plane area as part of the PAL 3 project at Terminal 3 of Ben Gurion Airport. The work in the project includes - implementation of soil work, concrete, skeletal systems and finishing, structural changes and extensions to existing structure and in extensions D and C. Preparing aircraft parking area around extension E. |

||

|

||

|

||

|

||

| Beit Shemesh Bridge | ||

Construction of a bridge connecting neighborhoods to allow for increased traffic volume. A replica of the parallel bridge. A cast prestressed concrete bridge. Expected completion – Feb 2021. Construction of a bridge connecting neighborhoods to allow for increased traffic volume. A replica of the parallel bridge. A cast prestressed concrete bridge. Expected completion – Feb 2021. |

||

|

||

|

LRT – OCS Inspection for Operation & Maintenance |

||

|

1.

Presence of regulated / auto tensioned contact wire: ✓ Presence of fixed contact wire; ✓ Geometry of the track (straight, curve, curve and counter curve, etc.); ✓ Altimetric trend of the track (presence of sections with constant slope, sections with variable slope, flat sections, etc.); ✓ Pushing the pantograph; ✓ Geometry of the contact wire (stagger, height, sag in the middle of the span); ✓ Environmental conditions; ✓ Presence of masses concentrated on the contact wire; ✓ Presence of masses distributed on the contact wire; ✓ Nominal tension of the regulated or fixed contact wire; ✓ Length of the fixed contact wire; ✓ Length of the adjusted contact wire;

|

||

|

2. Checking and identification of the ocs components and sub-components- Not subject to wear but in status of conservation not adequate or missing due to: ✓ Degradation; ✓ Damaging; ✓ Lack of adequate maintenance; ✓ Physical lack of the component; ✓ Modifications occurring with respect the installation time. |

||

|

||

Road 531 project is one of the most complicated transportation projects done

Road 531 project is one of the most complicated transportation projects done

Contact wire check and measurement

Contact wire check and measurement